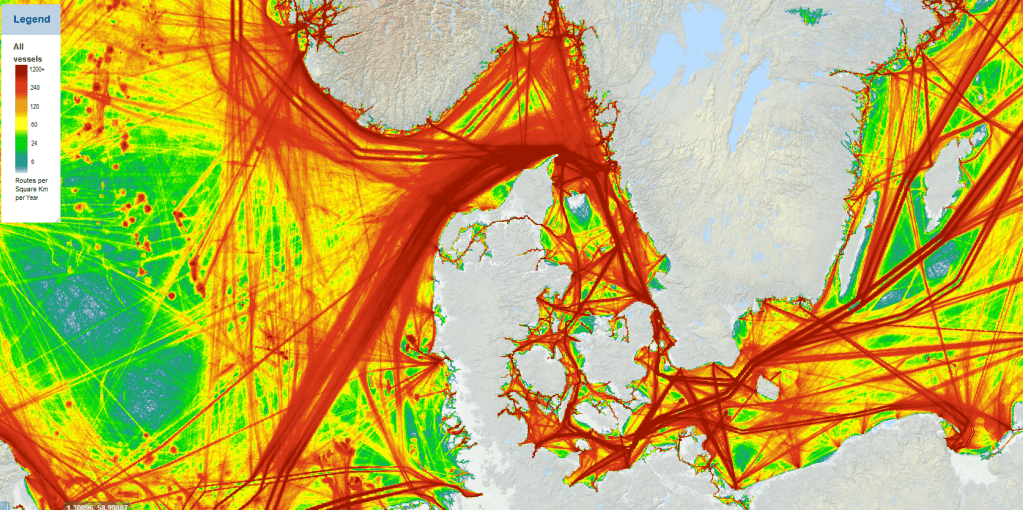

The interconnectivity of offshore cables both considering electromagnetic and fluid transport is essential for the transport of vital services for modern society. Some of the cables for instance those responsible for our high-speed internet are massive often spanning the entire length of the Atlantic ocean before reaching the Americas. This ensures that information flows easily between international borders and countries allowing the fast and reliable exchange of knowledge.

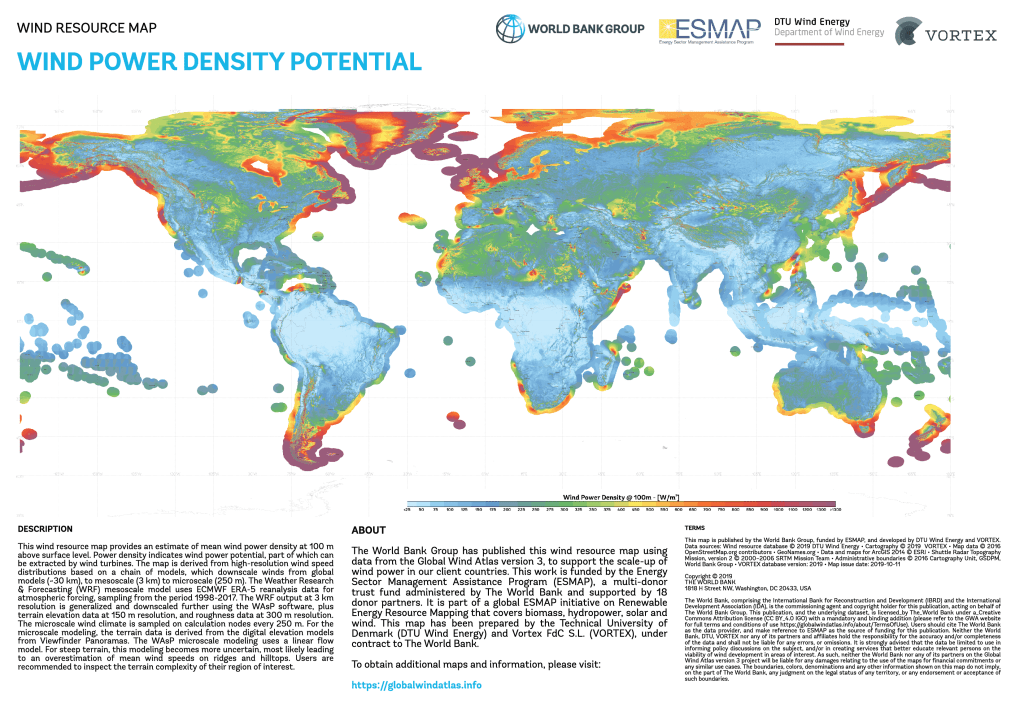

Furthermore, critical infrastructures such as oil and gas installations, offshore wind parks and transformer stations also have cables of varying types and design, which in certain instances as is the case with offshore wind farms, can span wide areas of the seafloor ensuring proper interconnection between transformers and producers of the electricity.

However offshore cables are complex structures with a variety of challenges posed such as scour, erosion, fatigue, biofouling and scaling to mention some of complexities which we will consider in this blogpost.

- Types of offshore cables

- Installation of cables

- Maintenance of cables

- Fatigue problems in offshore cables

- Miners rule

- Erosion

- Scour protection methodologies

- Perspectives

- References

Types of offshore cables

There exist a plethora of offshore cables whose design is specifically tailored to individual usages. For electrical cables one of the key design characteristics is the array interconnectivity ensuring that electricity is easily transported from offshore wind farm arrays towards transformer stations. These transformer stations transform the electricity from Alternating Current (AC) to Direct Current (DC). This transformation is done to allow for the electricity to be transported vast distances without loosing effect from offshore to onshore locations.

However we are just scratching the surface for the types of offshore cables which exists, others have the capability of transporting heavy viscous fluids under a variety of temperatures and pressures. These are typically used in the oil and gas industry where fluids and liquids are transported through pipes constructed from specialized engineering materials ranging from composites to hardened steel.

Another type of cable present throughout the globe are the internet cables crossing the oceans. These have been installed to ensure that the information flow can be shared internationally in lightning fast speeds. These enables everyone present in the developed world to communicate with each other sharing opposing views.

These cables are necessary to allow online trade enabling fast transactions across the Atlantic increasing the liquidity of markets and enabling secure transfers to be made. The development of the internet cables have taken multiple centuries to construct effectively.

Now one may wonder how does the offshore cables get installed in the first place?

Installation of cables

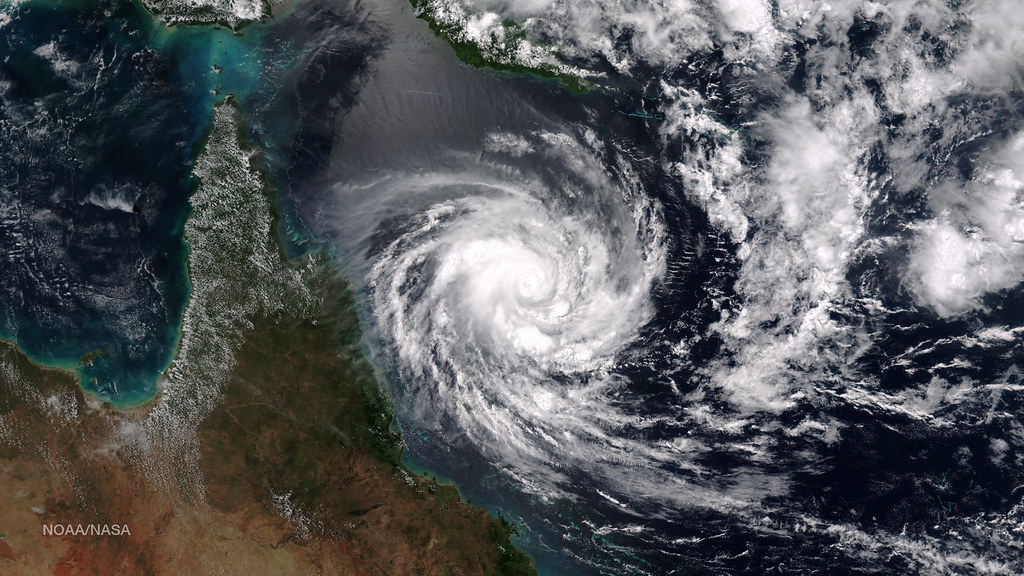

The installation process is difficult and requires specialized equipment, crew and optimal weather conditions in order for the successful installation at sea. Weather conditions are location dependent and thus may cause delays in schedules. Such delays are costly and almost unavoidable considering the inherent uncertainty with accurate weather prediction. This means that advisors typically provide weather windows which are probabilistic timeslots of allowable work conditions for the vessels to operate in.

Weather windows and uncertainty

These weather windows are typically calculated utilizing high-resolution weather and hydrodynamic models specifically tailored towards area in question. Such high-resolution modelling requires refined data collection systems alongside specialized personnel able to calibrate and utilize the advanced mathematics necessary for constructing accurate local models.

However, despite these precautions and the extensive upfront effort required to develop accurate weather windows, probabilistic assessments remain susceptible to errors. These errors often arise from numerical approximations and the inherent limitations of abstracting real-world complexities into simplified models.

Monitoring in-situ conditions

As a result, the ship owners are often still relying on in-situ weather equipment’s such as ADCP’s, FLiDARS and weather radars before determining whether to conduct the work campaign or not. Those decisions are ultimately resting on the captains experience, information sources and available crew up to the day of the installation.

Finally when the crew and vessels are ready to work offshore the challenges becomes laying down the actual cables since the rollers and ship equipment needed for transporting and securely laying down the cables are expensive and hard to manufacture.

This leads us to the operating stage of the offshore cables where the introduction of maintenance criteria becomes relevant.

Maintenance of cables

After installing the cables in the subsea, the next problematic is ensuring that the cables are kept maintenance free, in the sense that the majority of cables will be subject to a variety of problems including biofouling, scour, buckling and fatigue.

Some of these problems will emerge immediately in the case of failure events such as, buckling and fatigue. Here failure induces immediate cutoff of material transportation which will halt immediately. However other types of failures are difficult to recognize as the gradual degradation leads to falling performance. This is the case with biofouling and scaling type failures.

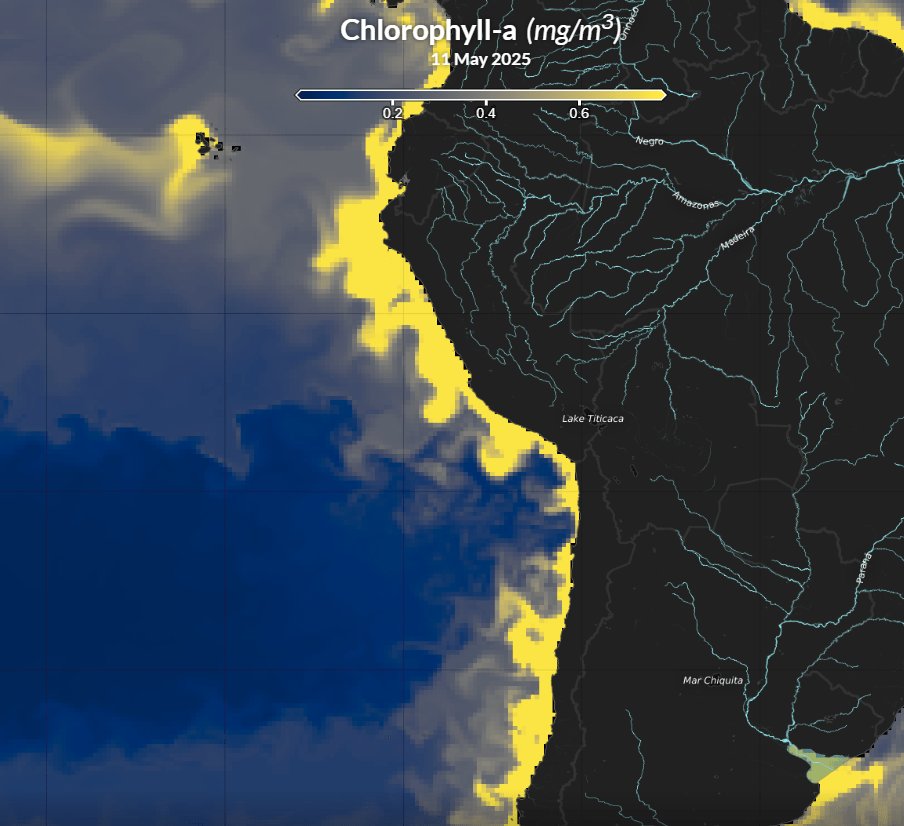

Such problems can require frequent inspection in order to understand and elucidate extent of the problem. This is particularly true in cases where pipes distribute fluid matter towards recipients such as oceans and rivers where environmental damage can occur which is the case for transportations of sewage and other types of nutrient loadings.

Nutrient loading and biofouling problems

When nutrients are transported towards the sea issues can arise in the natural growth of vegetation within pipeline specimens. Here algae and other marine life can grow and feed on the available nutrients possibly restricting and obstructing flow completely.

In such cases it may be necessary to first visually inspect the pipeline and afterwards manually remove the overgrown biofouling. In rare cases it may be necessary to utilize heavy equipment such as hoses are robots to effectively remove everything blocking the pipeline.

Transportation of crude oil

Some of these specialized cables are used for offshore transporting of crude oil towards the refineries onshore. As crude oil is a quite heavy substance difficult to transport vast distances, it is necessary for high pressures leading to increased requirements for the design.

The offshore cables have high pressure fluids flowing for multiple kilometers ensuring the safe and sound transport of the black gold. This means of offshore transport considering multiple kilometers lead to frictional resistance which in turn demands the inclusion of pumps and vents for safety reasons.

Furthermore the complexities are extensive when considering floating designs as the hanging poses problems with bending moments increases risks of catastrophic failure not to mention stability due to marginal current events happening during stormy seas and possibilities for dynamical failure due to vibrations from vortex shedding.

Some other problematics with fluid flow in pipes arise from the continual exposure of corrosive substances leading to problems with cracks developing within the pipe inner walls not to mention problems with scaling and reduced fluid flow within the offshore cables.

Couette Poiseuille flow

Fluid flow within the pipes are typically frictional which under constant flow and pressure leads to mathematically consistent fully developed Couette Poiseuille flow profile where velocities are increasing towards the center of the pipe while fluid flow pressure is falling in the streamwise direction at a constant rate.

The flow profile is derived considering the mean flow, meaning that instantaneous fluctuating flow profiles are chaotically moving inside the pipe fluctuating due to differences in pressure and friction. This is fluid profile is maintained until the pressure drop is at a point where fluid flow cannot be maintained. The constant pressure drop due to frictional effects demands the inclusion of accelerators and pumps along the length of the pipe. These ensure that frictional losses are accounted for while maintaining a somewhat constant flow pressure.

Flow pumps and pressure variations across pipes

The pressure inducers are included at set distances ensuring that the distribution and connectivity of the pipes are adequate to accommodate the expected fluid flows. Furthermore, it is important to ensure that temperatures and pressures are kept within the design range of the cables not to cause pipe fractures or failures.

Some of the types of failures which may be included in offshore cables include ultimate limit states which in worst cases can lead to leaks causing cause environmental catastrophes with significant ecological damage and loss of marine life as a consequence. Famous instances of such fractures and leaks include the Ekofisk blowout and Deepwater horizon incidents. The leaks are difficult to accurately monitor due to the nature of happening underseas and worse yet, the oil and gas spilling in deep oceans, can drift for extended ranges following stratified ocean currents.

Thermoclines and stratified flow

This type of stratified flow occurs across the globe and is typically characterized by salinity temperature gradients at various depths. The exact location of the saline thermocline is highly dependent on small temperature variations across the globe. The sea-surface temperatures are tempo-spatially varying and slowly changing across the seasons, leading to a dynamical system of continual rise and falls throughout the year.

The weather pulls on sea surfaces inducing currents and astronomical variations causes tidally varying sea levels causing influxes of fresh saline water penetrating the thermoclines ensuring that ecosystems are provided with variations in saline waters.

These types of currents and flows are difficult to accurate model and predict and can cause vibrational damage of the cables as their movements in the transverse direction are dependent on the induced vortex shedding from varying flow structures across the geometry. The vibrations and movements induced by oceanic forces over time lead to the wear and tear of the cables causing lasting damage through fatigue induced limit states.

Fatigue problems in offshore cables

Normally, materials fail gradually through a continual and consistent stress induced within the specimen. This type of failure is called fatigue and is present in all materials whether that be steel, concrete or wood. However for offshore cables, typically made from steel and other composite materials the fatigue limit states arising from normal wear and tear is a result of the continual and rhythmic exposure to strains from environmental forcing such as currents and waves.

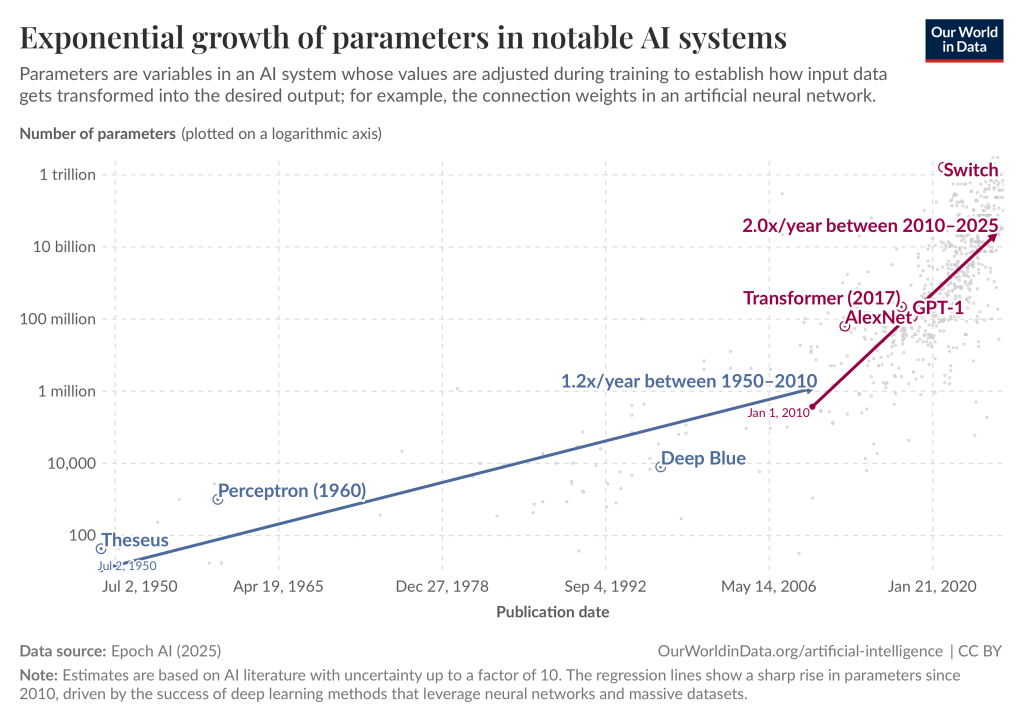

This rhythmic exposure is chaotic and ergodic in nature and thus difficult to consider in theoretical designs. Due to this ergodicity, the designs of fatigue resilient offshore cables is subject to the treatment in a probabilistic sense through use of abstractions. A famous example of this type of abstraction stems from the railway industry. Here rails were treated probabilistically when dealing with the constant and frequent pressures from trains passing over them leading to the development of miners rule.

Miners rule

Miners rule transforms ergodic randomly occurring loads into a linear superposition of constantly occurring loads with varying magnitude and frequency.

The reason for converting the probabilistically occurring loading into something regular, is to allow probabilistic treatment useful for general purpose design of a variety of materials and geometries.

The superposition theory allows prediction of the lifetime and performance during expected lifetime enabling engineers and scientists to estimate behaviors spanning broad applications. However it is important to state that this prediction only provides an estimate that inherently is associated with uncertainty.

The underlying uncertainty is difficult to quantify as there are no methods for accurately assessing the underlying mechanisms governing the growing cracks and fractures which eventually ends with the specimen failing.

Micro fractures

The procedure of fatigue failure is thus one where micro fractures are growing with time, creating the foundation for larger fractures to grow until the bearing capacity of the specimen is exceeded causing a breakthrough.

The movements causing fatigue related fractures and damages in offshore cables arise naturally from dynamical effects such as vortex shedding happening as a result of the hydrodynamic forcing to the specimen.

The hydrodynamic forcing across the specimen causes other natural phenomena to occur such as the introduction of bed movements from increased shear stresses in the seafloor bottom leading to effects such as scour and erosion.

Erosion

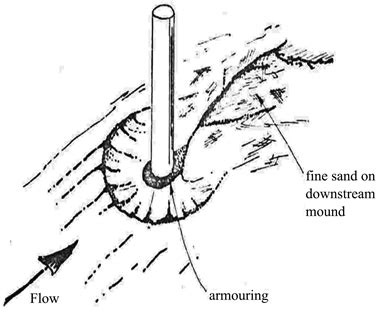

Erosion is a well studied although poorly understood phenomenon occurring to all structures and objects exposed to hydrodynamic forces placed on soft foundations.

Erosion creates holes where sand, sediment and other things are removed undermining the foundation of offshore cables and structures. These holes, called scour holes, possess a significant problem in the offshore industry as their predictability is incredibly difficult to do accurately however essential to account for.

The reason predictability is so difficult lies in the highly complex interactions between sediment and fluid. A process which is dependent on a multitude of factors, such as sediment type, flow conditions, structure and time.

Time is an important factor as fluid flow is influenced by the scour hole development and visa versa. Generally a scour hole takes time to develop fully and even then, dynamics can change due to backfilling of sediment.

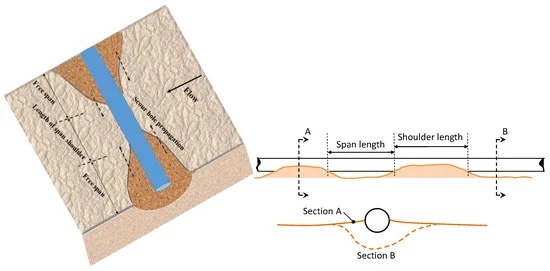

Thus the highly dynamical nature behind scouring is difficult to accurately account for and specifically for cables, the three-dimensional scour effects can cause the generation of so-called ‘shoulders’ carrying the weight of the cable for spans which for specific scenarios can be quite extensive.

Shoulder generation

The shoulder generation stems from scouring and migration of sediments, typically sand, transversely from the main direction of the cable. The cables hangs and possibly sways freely between the shoulders and should therefore be sufficiently strong to uphold its own weight during such spans.

If the sacking of the cable becomes too extensive, the initiation of cracks and mechanical so-called ‘hinges’ can occur enabling rotations without any resistance towards bending. These rotations can then cause damage and possibly failure in rare scenarios.

Other motions which can cause irreversible damage is bending due to zigzagging resulting in a snake like layout and increasing risks of fractures within the cable. Some of the reasons for this phenomenon to occur lies in the longitudinal heat stresses whose presence increases risks of material failure.

Cable lengths

The length of cables are often hundreds of kilometers, meaning that individual cables have the possibility of shoulder generation for multiple instances along the entire length of the cable.

The exact depths and lengths of the shoulders are hard to predict and the variety of factors influencing scour holes causes issues for constructors as remedies for the phenomena are difficult if not impossible to implement over the entire length of the cable.

This issue is highly dependent on the type of cable, with large diameter cables leading to larger scour holes while smaller diameter cables have less scour as vortex generation is highly dependent on geometry.

These creates the need for extensive surveillance as the issues could arise for multiple areas along the cable. The resulting holistic view is a mosaic of complex issues where scour is one when considering offshore cables involved in the transportation and distribution of fluids and electricity. Luckily for us there exist some remedies for creating long-lasting permanent solutions to sedimentation problems.

Scour protection methodologies

Scour protection methodologies exists including rock embedment’s, nets and stone covers to mention some of the main types of scour protections. Issues still remain within scour protection methodologies with one of the recent ones being that smaller diameter sediment particles are sucked up between larger diameter rocks causing issues with stability of complex breakwater installments.

The degree and extent to which scour protection is included varies depending on the location of the pipeline. The degree of protection needed for ensuring a proper design increases when nearing the shoreline as waves and other coastal phenomena introduce bed movements. This results in cables needing to be buried to ensure a stable shoreline landfall.

To dive a bit deeper into the reasons for requiring burial of cables in the surf zone we will have to consider the physical dynamics taking place there. In the surf zone, breaking waves are causing increased shear stresses leading to rapid scour hole development. The increase in shear stresses causes sediment longshore. This burial is thus critical for ensuring the stability of the cable during landfall.

Furthermore, the burial process also ensures that external actors are not accidentally damaging the cable through interactions in the surf zone. Possible incidents could be small vessels tearing over cables with their anchors and individuals stumbling over the cable.

The locations of the pipelines and overall burial status is overviewed by utilizing side scanning technologies. After initially locating the pipeline, side scanning allows for the measurement of bathymetry in the vicinity and on top of the often buried pipelines elucidating buckling, burial and crack related problematics.

Alternatives to burial and small rock embedment

Burial techniques is critical when considering the landfall scenarios however within other parts of the offshore environment multiple other methodologies for scour protection exist, some of them are rip-rapping and geotextiles. These consists of large rocks while in other areas of the world concrete slaps and blocks are used as well. The feasibility of the individual methodology relies on a multitude of factors including the availability of concrete, rocks and geotextile material.

Another type of scour protection which recently started to gain traction is the inclusion of artificial rock reefs. These reefs are constructed large boulders offshore whose existence afterwards promotes biodiversity and overall ecological improvements through the introduction of hard structures in an otherwise barren landscape.

Perspectives

The elucidation of undersea cables is essential as it contributes to the understanding of some of the major critical infrastructures which enables modern day society to exist. The maintenance, erosion and scour of cables are under appreciated feats of engineering enabling modern day society to exist.

The integrity and continued usage of cables undersea are critical for the development of modern necessities such as internet and energy security. Installation is complex, requires planning ahead and is inherently uncertain due to weather phenomena.

Finally, locations offshore cables as critical infrastructure poses key challenges in international trade and security. The control of international sea is difficult and sabotages of key supply lines can disrupt countries access to information and energy causing serious harm to the general population.

References

Morimatsu, H.; Tsukahara, T. Laminar–Turbulent Intermittency in Annular Couette–Poiseuille Flow: Whether a Puff Splits or Not. Entropy 2020, 22, 1353. https://doi.org/10.3390/e22121353.

Najafzadeh, M.; Oliveto, G. Exploring 3D Wave-Induced Scouring Patterns around Subsea Pipelines with Artificial Intelligence Techniques. Appl. Sci.2021, 11, 3792. https://doi.org/10.3390/app11093792

Leave a comment