Recent advances in floating offshore wind design poses a major revolution within the existing fleet of engineering solutions for offshore infrastructure. This breakthrough in technology allow for the construction of turbines at locations previously inaccessible due to the water depths observed offshore.

The floating concept allows turbines to be placed further offshore where the general wind velocities are higher. With higher general wind velocities comes an increased wind energy output corresponding to an increased amount of electricity produced. However placing floating turbines leads to higher challenges within the offshore industry as the general stability, mooring and installation becomes increasingly challenging offshore.

As the floating concepts are tested, problems are elucidated within both fatigue related phenomena, corrosion, mooring, installation, maintenance, cables and stability not to mention key issues involved when building an array of floating offshore turbines. We will try and elucidate some of these problematic uncovering the fundamental complexities within the offshore floating wind turbine industry.

- Wind harnessing offshore

- Installation of floating wind turbines

- Mooring of turbines

- Offshore cables and array layout

- Stability of floating systems

- Maintenance

- Decommissioning

- Perspectives

- References

Wind harnessing offshore

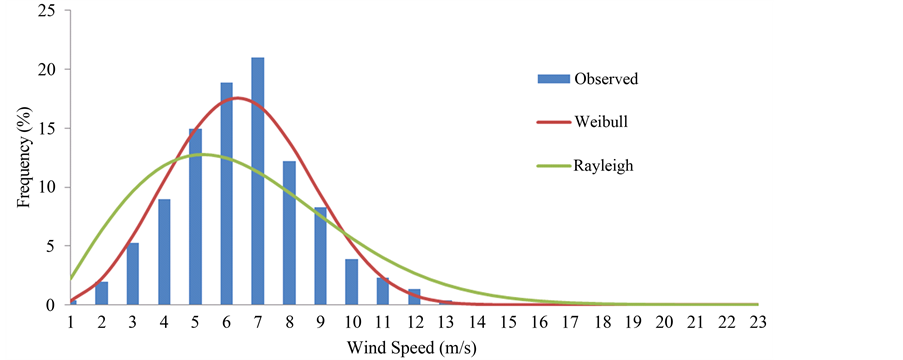

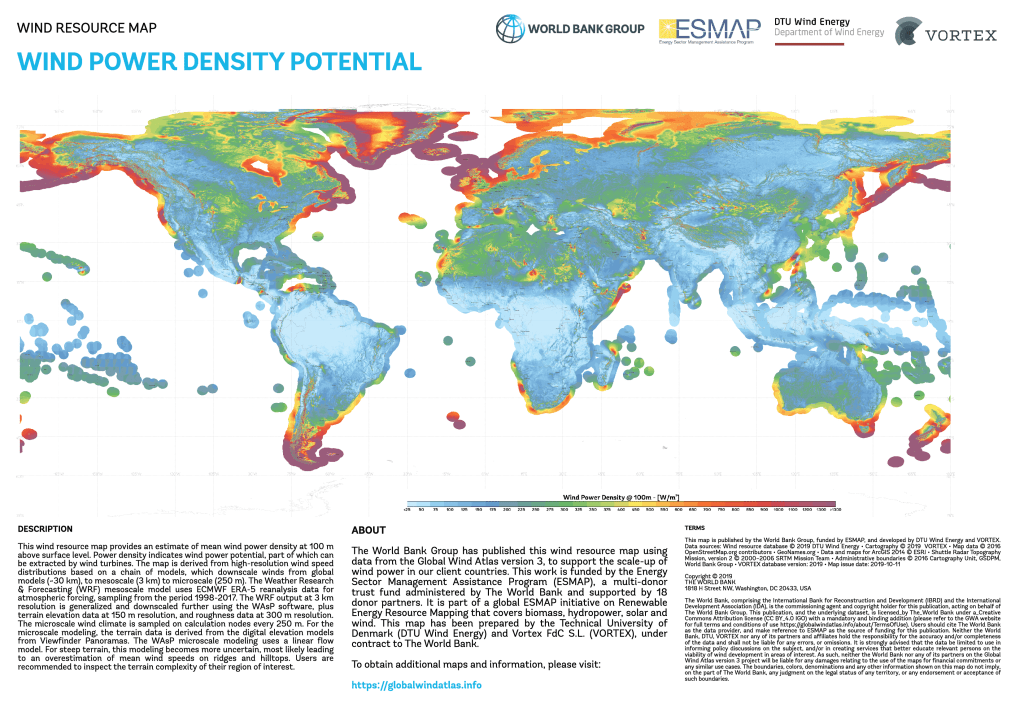

The wind energy curve follows a Weibull distribution. This distribution is skewed towards higher numbers leading the wind energy output to be favorable when being placed offshore. The wind turbulence is generally smaller offshore as the roughness is decreased at sea as compared to onshore.

The turbulence intensity is negatively correlated with windspeed meaning that higher wind speeds leads to fewer fluctuations when analyzed over a spectrum length scales. As the wind speeds increase offshore, the general turbidity decreases which again benefits the power producers as their turbine performance is better when harnessing wind energy from flows with less turbulence.

Therefore the two-pronged increase in offshore wind energy output provides a lucrative proposition for wind park developers as their revenues are dependent upon efficient and maximal power production while simultaneously requiring the electricity grid to be able to consume the produced electricity.

Imbalances between production and consumption

This leads to a conundrum when the amount of offshore wind is built up, the consumption versus production becomes skewed leading to a dramatic fall in electricity prices. This in turn means that the produced electricity becomes harder to sell to customers causing some windfarm owners to cut production in an attempt to balance out demand and supply sides.

The supply side issues with concurrent power production from renewable energy sources is growing internationally as the green transition slowly develops. These newly uncovered challenges poses great risks towards the continual development of offshore wind and solar parks. Some of the solutions proposed to this conundrum includes development of battery parks onshore made from large lithium ion batteries capable of storing electrical energy as a means to balance out the fluctuating supply side.

Related read: Challenges in offshore cable Installation and maintenance

Furthermore, the energy security side is more challenging to uphold as the external factors controlling the supply side are inherently ergodic as wind and solar production is concerned. This means that unlike coal and oil fired powerplants, the production fluctuates dramatically during the day, unable to be controlled which subsequently can cause outages during times of low-wind and cloudy weather.

Outtages and blackouts

As a result of the transformative energy grid systems these outages are believed to become increasingly frequent if no energy storage solutions are implemented. In worst case scenarios. the outages can cause problems in healthcare industries where professionals during operations can lack sufficient lightning or blackouts can cause disturbances in other electricity heavy industries such as manufacturing and production.

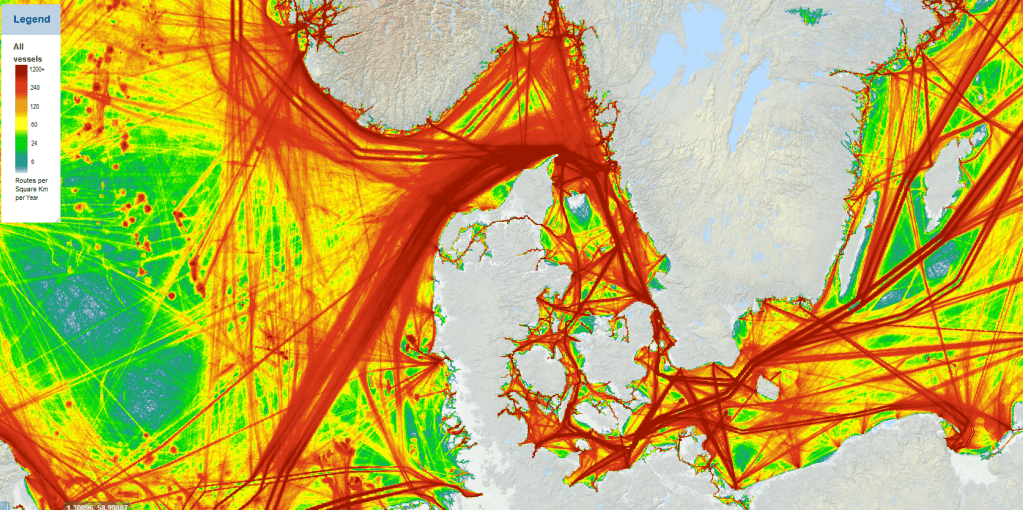

The energy production of offshore wind farms are not only influenced by macroscopic atmospheric flow movements but also by local effects dependent on the placements of individual turbines as these absorb incoming wind energy leading to reduced wind potential downstream of the turbines. These effects are called lee wake effects and is thoroughly studied in an effort to understand the best ways to mitigate and optimize placements of offshore turbines.

Lee wake effects of offshore wind

The lee wake effects of offshore wind farms is an important phenomenon responsible for decreased efficiency of offshore turbines. It arises from the placements of turbines which in certain cases shelter each other from the incoming wind as they absorb as spectrum of the available energy upfront with a decreased potential downwind.

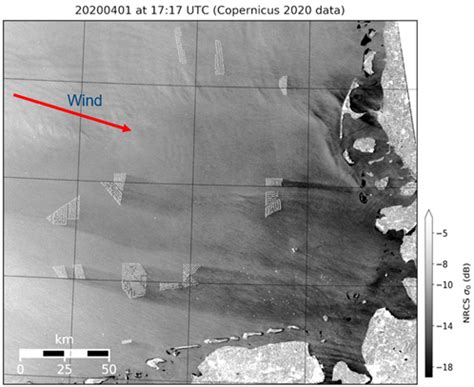

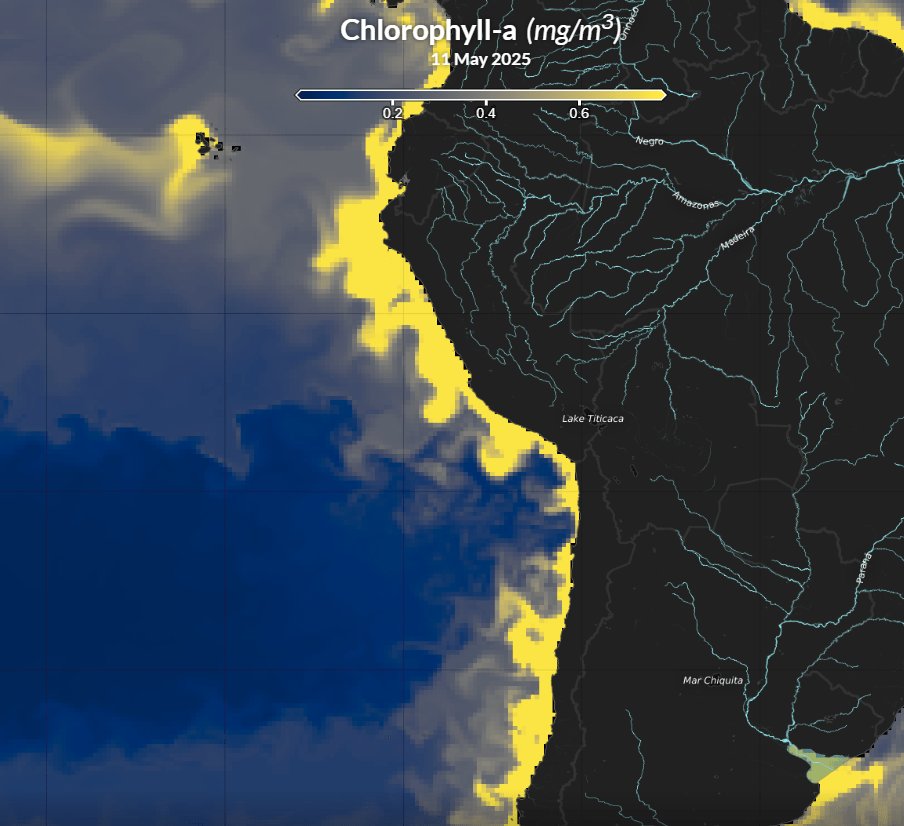

The lee wake from offshore wind farms is extensive whose extent can be measured for 100’s of kilometers with a decreased influence further out. The influence of offshore wind farms on the general wind climate is difficult to quantify effectively as the long-term measurements of changed wind climates cannot easily be obtained.

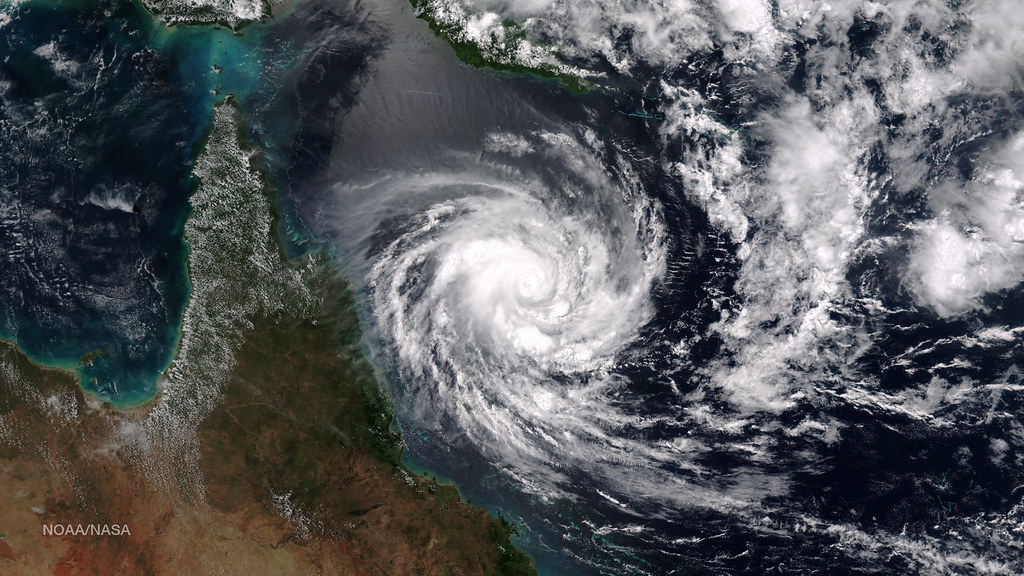

However through satellite imagery it is possible to elucidate effects of sheltering around the windfarms in an instantaneous manner. This shows that the effects are significant even for distances far outreaching the initial perimeter of the offshore wind farm. As the environmental impact assessments are hard to estimate for considering cumulative effects it must be based on an holistic qualitative assessment considering a broad variety of factors.

Related read: Environmental impact of offshore infrastructure

This broad range of factors include birds, mammals, noise, wind disturbance, visual identity, marine fauna, invasive species and seafloor integrity to mention a few of the factors considered when constructing large infrastructure projects.

Installation of floating wind turbines

The installation of floating offshore wind turbines is easier than fixed bottom turbines as they can be towed from shore unto the offshore environment without needing specialized vessels capable of lifting massive loads from the complex steel structures that are necessary for establishing a safe environment offshore.

Typically heavy vessels designed with large anchors and piles driving equipment are necessary for the installation of fixed bottom structures.

However with the installments of floating turbines other types of vessels are necessary specifically mooring and towing type vessels are necessary for transporting the floating platform to the end destination. Furthermore when towed towards the end destination it is necessary to ensure sufficient anchoring such that drifting and tilting is avoided through all costs.

Mooring of turbines

The exact mooring details of the individual turbines are inherently complex due to the fact that waves, currents, wind loading and soil interactions are all unknown. Furthermore, the individually spaced and distributed floating turbines are all individually unique in their placements and subsequently loafing to which they are exposed.

This means that assumptions and conservative design considerations are necessary in order to design a scalable floating wind park capable of being moored in various locations. The challenges with soil stiffness variations poses significant challenges, furthermore the fact that it is placed under water means that the scour and erosion problematics become critical to understand properly.

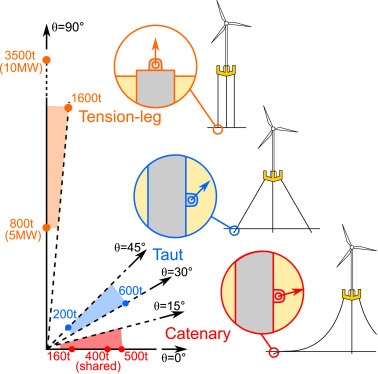

Anchoring types

Unlike the typical anchors found in ships, the foundational anchoring of a floating wind turbine is difficult to assess correctly as it should be durable enough to withstand significant loading from storms and due to long term exposures towards the corrosive sea environment filled with salt and biofouling.

Anchoring techniques vary and current technologies are still immature to a point where the individually chosen technologies are competing on price and availability. The different techniques have individual strengths and weaknesses which all depend on the weather, installation and configuration of the individual offshore wind parks.

New innovations are underway leading to new understandings of anchoring and mooring. These are being developed through bilateral agreements leading to international contributions towards a more sustainable future through inclusion of the renewable floating energy parks.

These innovations will also consider the broad variety of interconnectors and cables necessary for fulfilling the energy transportation needs, specifically from offshore towards onshore as it is critical for operability of the entire offshore wind park.

Offshore cables and array layout

The next issue after ensuring proper anchoring is the need for cables to be installed into the caisson from the bottom. This interconnection is quite challenging to get right and can result in a multitude of issues such as fatigue related damages in and around the cable connection holes, also issues relating to the hanging and scour around the cables can lead to a variety of issues including shoulder generation, burial and bending of the cables.

Related read: Challenges in offshore cable Installation and maintenance

The array configuration needs to consider specifications of the individual cables ensuring that they don’t bend and get destroyed easily. Furthermore the floating stability of the individual cables is also critical to consider since they may be too heavy and crack from the induced bending moments when dragged towards the bottom of the sea floor. At the midway of the cable being carried downwards towards the floor an intermediate floater is typically included in an attempt to reduce risks of induced bending moments from floating movements of the platform.

These motions will occur during stormy and normal operations and could significantly degrade the performance of the cable considering long term deployment. Furthermore when the cable is nearing the sea floor bottom it is necessary to ensure that bending moments of the bottom are accounted for as the angle between seafloor and surface is critical to hold below a certain level as the flexural stresses can cause long term fatigue induced failures over the lifetime of the floating structure.

Finally the cables are securely anchored to the seafloor bottom through a variety of measures including geotechnical secure anchors, concrete boxes and bored piles. This ensures a fixed endpoint of the cables while simultaneously ensuring that they keep flexible absorbing the rhythmic movements of the floating turbine.

We have now considered the anchoring and cable moorings of the floating turbines, next let’s consider the overall stability of the entire floating structure.

Stability of floating systems

The overall stability of the floating offshore wind farms is a delicate balance between hydrodynamic, aerodynamic and geotechnical forces all interacting in a nonlinear manner.

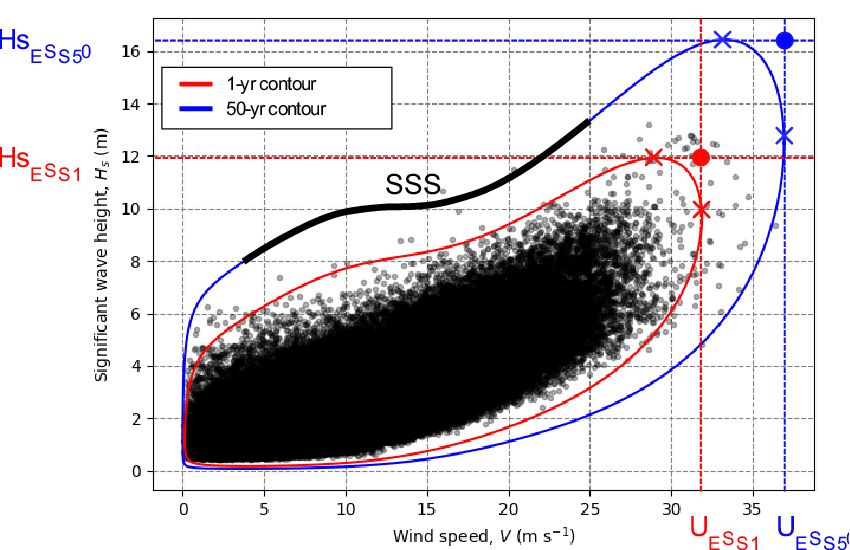

The marginal events dominating the ultimate limit designs constitute a fundamental conundrum as the exact distribution of extremes remain unknown the engineer has to choose an underlying function whose extrapolation determines the design level to which design should be based.

The extrapolations require careful and considerate analysis ensuring rigorous mathematical vigor such that underlying assumptions are upheld. The choice of distribution lies often involves considering multiple different distributions all fitted to the available and often calibrated hindcast model where site specific data is retrieved and considered based on state-of-the-art models.

Environmental contours

Another important factor to consider is the overall combined effects of wind, waves and currents during normal operational conditions. The interplay between these external forces has puzzled scientists for centuries as their interactions are not fully understood yet. Thus the frequencies and responses for the floating platform often times need to be tested in lab scale environments before design criteria can be established in a holistic manner.

The loading of the platform is derived from a collinear scenario where individual loading factors from currents, winds and waves are combined in a redundant manner without adding together the individual contributions linearly leading to an overestimate of the combined loading.

Maintenance

The maintenance aspect of the floating offshore wind system is critical and arguably more important than fixed systems as the dynamics of the entire structure can lead to an increased rate of failure in particular for subsystems such as the individual bolts and nuts not to mention hanging cables from the bottom of the turbine.

The maintenance of the turbines is a significant cost for the owners of the offshore wind parks which impacts their levelized cost of energy offered in the markets. The maintenance of offshore wind parks include different tasks such as inspections of steel structures assessing the amount of corrosion and to which degree the integrity of the structure remains valid.

Furthermore maintenance also includes oiling up the individual bearings of the turbine specifically considering the turbine nacelle as the main bearing carrying the wings needs a substantial amount of maintenance, causing issues when considering the need to shut down the turbine during maintenance.

When technicians and engineers go out to assess the individual turbines they need to be transported out to the turbines. This often times mean that boats are needed sailing out to bottom of the turbine, allowing them to climb up on ladders requiring calm sea conditions. In an attempt to circumvent these issues, modern day turbines instead utilize helicopters where individual platforms are placed on top of the turbine and technicians and engineers can subsequently be lined downwards towards the platform center.

This way of transporting personnel allows for quicker and more reliable transport options while simultaneously ensuring that the turbines can be more efficiently inspected and maintained with fewer personnel available. The last phase of the floating offshore wind farms include the decommissioning stage where individual structural elements are recycled in the most efficient manner reducing the overall environmental impact of the offshore wind park.

Decommissioning

The decommissioning phase is a critical part of the holistic life of an offshore floating wind park. The steel is floated back towards land and remelted down enabling construction of new steel members ready to be taken offshore or within other industries. The amount of recycled steel from offshore wind farms is a significant portion of the entire structure, while the biggest recycling issue stems from the utilization of the offshore wind farm wings which are created from fiber glass composites.

These fiber glass composites are inherently difficult to recycle as they cannot in the same way be melted down due to the inherent material characteristics. Furthermore they are not transferable to other industries as these specially designed composite materials are not utilized in other parts of society. Therefore a large amount of the offshore wind farm wings end up being shredded and deposited towards landfills where they fill up otherwise useable land.

Research into possible use cases of the offshore windfarm wings is currently being investigated and include floating offshore wind farm foundations created by shredded fiberglass material which is subsequently glued together into a new composite material whose fibers are oriented chaotically resulting in a highly complex material whose strength characteristics are not easily determined. Further research is needed as the amount of decommissioned wings is expected to increase significantly in future society.

Perspectives

The floating offshore wind industry is growing rapidly and is expected to play a larger part in the coming years as technologies and investments mature from the current stage.

The technologies for mooring, installation, maintenance and decommissioning are constantly evolving and will impact the future offshore wind parks significantly considering expected lifetime, operation and subsequent recycling.

As the floating offshore wind industry advances, it opens up unprecedented opportunities for sustainable energy production. This is the next natural steps of renewing our current energy production capabilities enabling a brighter, cleaner and more sustainable future for the upcoming generations.

References

Cerfontaine et al. (2023). “Anchor geotechnics for floating offshore wind: Current technologies and future innovations” https://doi.org/10.1016/j.oceaneng.2023.114327

Uchida. (2020). “Effects of Inflow Shear on Wake Characteristics of Wind-Turbines over Flat Terrain” https://doi.org/10.3390/en13143745

Papi et al. (2022). “Derivation of Met-Ocean Conditions for the Simulation of Floating Wind Turbines: a European case study” http://dx.doi.org/10.1088/1742-6596/2385/1/012117

Leave a comment